Kanban is a challenge administration strategy for almost any step-by-step course of to extend effectivity, scale back waste, and assist a enterprise enhance.

Though Kanban was developed within the Nineteen Forties and Nineteen Fifties to spice up manufacturing effectivity at Toyota factories in Japan, the system has been tailored to many industries, together with software improvement, publishing, and retail.

Kanban is especially efficient for steady supply workflows, comparable to content material marketing and stock administration, since it will probably “pull” work via a course of.

A ‘Pull’ System

To know how Kanban works, think about a Toyota manufacturing plant within the Nineteen Fifties that makes elements for cars.

Manufacturing processes on the time have been targeted on “pushing” elements by means of as shortly as attainable. Machines have been optimized to supply. Staff of the period might have been paid “piece work,” which means their revenue trusted what number of elements they made per hour.

Optimizing manufacturing output seems like a good suggestion till you understand that not all auto elements have the identical degree of complexity or require the identical period of time to make. At one machine, a employee is stamping out 50 exhaust manifolds an hour. One other station, nevertheless, is simply making 5 carburetors an hour.

To unravel this manufacturing drawback and associated considerations, engineers at Toyota started learning grocery shops.

How was it that everytime you walked into the native market the shop appeared to be stocked? In Japan, maybe, you have been all the time capable of finding rice, seaweed paper, and fish. In america, the native grocer all the time had milk, eggs, and bread.

Toyota found that grocery shops used visible cues to “pull” stock via the method quite than specializing in “push” models.

Think about the egg cooler at your native grocery store. It in all probability has a number of dozen eggs organized into stacks by measurement and provider.

Once you decide up a carton, you create an empty spot on the stack. That area is a visible cue that stock will must be refilled.

Later a retailer worker sees the cue and retrieves eggs from a stroll-in cooler behind the shop. Maybe it has been an excellent day and the shop bought a whole field of eggs.

That night, one other retailer worker checks egg stock and sees that there’s a whole field gone. This worker orders one other field of eggs to be delivered the subsequent day.

A shopper’s egg buy helped to tug eggs by way of the stock course of. That is simply the other of what Toyota had been doing earlier than Kanban. As an alternative of ready for a buyer to “pull” auto elements by way of the method, they have been simply making issues. That may be like a grocery retailer worker stacking eggs to the ceiling no matter gross sales.

Visible cues and “pulling” turned an essential a part of Toyota’s lean manufacturing course of and “simply in time” strategy to constructing automobiles. This strategy has helped Toyota develop into the most important automaker on the earth.

Boards, Lists, Playing cards

Toyota couldn’t essentially depend on a automotive salesman to restock, say, coupes. Somewhat it created a system of boards, manufacturing lanes (or lists), and playing cards.

- Boards include or encapsulate a challenge or a workflow.

- Lists include and sometimes prioritize playing cards that share an identical standing or attribute.

- Playing cards describe the duty, together with associated or supporting info.

The Kanban system depends on boards, lists, and playing cards to offer a visible illustration of the workflow. Lists on the fitting of the board pull playing cards from lists on the left.

At its most elementary degree, a Kanban board might have as few as three lists. These lists could be labeled “to do,” “doing,” “finished” — or “activity,” “in progress,” and “accomplished.” However the concept is that there are no less than three statuses describing the three primary phases during which a activity strikes via.

Venture Workflow

A typical Kanban board for a marketing or enterprise undertaking ought to embrace a number of lists. For instance, a marketing challenge may need lists for:

- Backlog gadgets which might be being brainstormed or that aren’t but able to have work finished.

- Duties which are able to be labored on. The very best precedence process ought to be on the prime of the listing.

- In progress is the place playing cards go as soon as work has begun.

- In assessment is the stage when duties are reviewed, accredited, or despatched again to “in progress” for extra work.

- Finished is the standing of playing cards when the work is accomplished, however the activity, akin to a Pandora marketing campaign, has not but run.

Playing cards are pulled from the left to the suitable via the workflow.

Take into consideration the lists on the correct aspect of the board as vacuums. When they’re empty or when there are few playing cards in these lists they “pull” gadgets from the listing on their left. So the “Executed” listing needs to tug gadgets from the “In assessment” record. The “In evaluation” listing needs to tug from the “In progress” listing, and so forth.

When a marketing specialist turns into obtainable, she takes duty for the merchandise on the prime of the “Duties” listing and strikes it to the “In progress” listing. As soon as one among her playing cards has made the journey to “Executed,” she begins once more at “Duties.”

A undertaking proprietor or supervisor strikes playing cards from the Finished record to an archive when the marketing activity is accomplished and strikes playing cards from the backlog into Duties as they turn into prepared for work.

A Particular Process

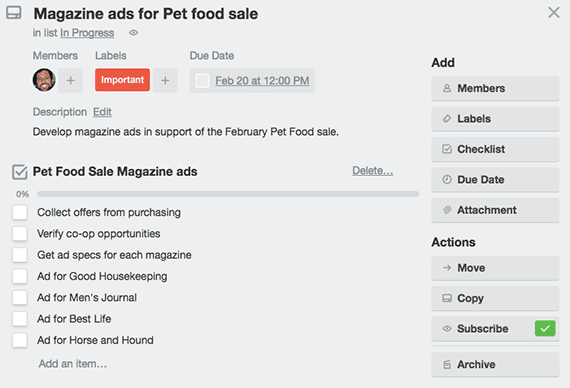

Every Kanban card has all the info a employee would wish to finish a process and should even embrace sub-duties within the type of a guidelines.

Playing cards are additionally the place for collaboration, as a number of card “members” can trade feedback, make strategies, or assist full checklists.

Kanban playing cards embrace all the info a employee would wish to work on a activity or it is going to no less than level them to different assets. It might additionally embrace sub-duties within the type of a guidelines or comparable.

Overcome Complexity

As ecommerce and retail companies develop, additionally they develop extra complicated processes.

To deal with this complexity, a enterprise might want to undertake some type of challenge and process administration. The Kanban system is one strategy. It might assist arrange these processes.